The Art of Engine Tuning Before ECUs: A Mechanical Symphony

In today’s world of computerized engine management, it’s easy to forget that vehicles were once tuned through purely mechanical means. Before Electronic Control Units (ECUs) revolutionized the automotive industry, tuning a car or motorcycle engine was truly an art form that required patience, skill, and mechanical know-how. This mechanical heritage still influences modern tuning culture across India, where young enthusiasts continue to appreciate both vintage and contemporary vehicles.

What is Engine Tuning?

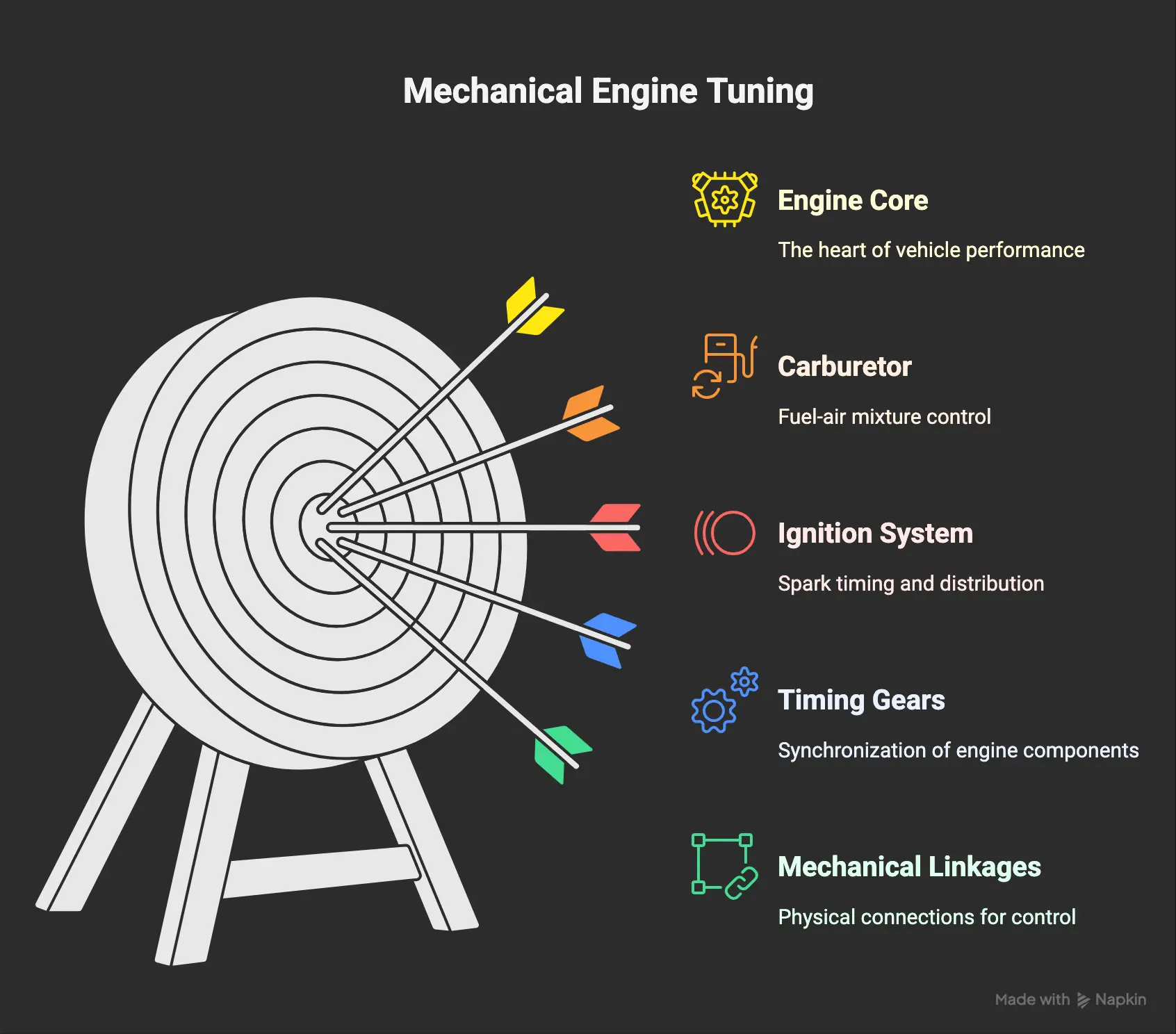

Before diving into pre-ECU tuning methods, let’s understand what engine tuning actually means. Engine tuning is the process of modifying an engine’s operating parameters to achieve optimal performance, fuel efficiency, reliability, or a balance of these factors. Today, this often involves adjusting software parameters in the ECU, but historically, it meant making physical adjustments to the engine components.

The Carburettor Era: Heart of Pre-ECU Tuning

The carburettor was the centerpiece of engine tuning before electronic fuel injection systems became standard. This mechanical device was responsible for mixing air and fuel in the correct proportions before delivering it to the engine’s combustion chambers.

How Carburettors Work

A carburettor operates on the Bernoulli principle, where air flowing through a venturi creates a pressure drop that draws fuel into the airstream. The main components that tuners would adjust included:

- Main Jets: These controlled the amount of fuel delivered during mid to high-range operation

- Pilot Jets: Responsible for fuel delivery at idle and low speeds

- Needle and Jet: Controlled fuel delivery during transition from low to high speeds

- Float Height: Determined the fuel level in the float bowl, affecting overall richness

- Air Screws: Fine-tuned the air-fuel mixture at idle

Carburettor Tuning Process

Tuning a carburettor was a meticulous process that required:

- Baseline Setup: Establishing initial settings based on manufacturer recommendations

- Jet Selection: Choosing appropriate jet sizes based on engine requirements and environmental conditions

- Synchronization: For multi-carburettor setups, ensuring all carburettors operated in harmony

- Mixture Adjustment: Fine-tuning the air-fuel ratio for different operating conditions

Many older enthusiasts in India still fondly remember spent weekends tuning the carburettors on Royal Enfield motorcycles or Ambassador cars, often developing an intuitive sense for engine performance based on sound, smell, and feel.

Ignition Timing: The Critical Adjustment

Ignition timing refers to when the spark plugs fire in relation to the piston position. Before electronic ignition systems, timing was adjusted mechanically and was crucial for engine performance.

Mechanical Distributors

The distributor was the heart of the ignition system, containing:

- Contact Points (Breaker Points): Mechanical switches that opened and closed to create the spark

- Mechanical Advance Mechanisms:

- Centrifugal Advance: Weights that adjusted timing based on engine RPM

- Vacuum Advance: Diaphragm that adjusted timing based on engine load

Timing Adjustment Process

Adjusting ignition timing involved:

- Using a Timing Light: A stroboscopic lamp that flashed in sync with the spark, allowing visualization of timing marks

- Rotating the Distributor: Loosening the distributor and rotating it to advance or retard timing

- Setting the Points Gap: Adjusting the gap between contact points to control dwell time

- Replacing and Gapping Spark Plugs: Ensuring proper spark plug operation

For many Indian mechanics who trained in the 1970s and 1980s, setting the timing by ear was considered a mark of expertise, especially in rural areas where timing lights weren’t always available.

Valve Adjustment: The Precision Work

Valve adjustment was another critical aspect of engine tuning that required mechanical skill and precision.

Mechanical Valve Trains

Before hydraulic lifters became common, engines used:

- Solid Lifters: Required regular adjustment as they wore

- Rocker Arms: Pivoted on shafts or studs to transfer camshaft motion to valves

- Pushrods: Connected the camshaft to the rocker arms in overhead valve engines

Valve Adjustment Process

Tuning the valves involved:

- Measuring Clearances: Using feeler gauges to check the gap between valve components

- Adjusting Clearances: Turning adjustment screws or replacing shims to set precise clearances

- Setting Valve Lash: Ensuring proper clearance for thermal expansion during operation

This process required rotating the engine to specific positions for each cylinder and working methodically through all valves. In India, this skill was often passed down from master mechanics to apprentices, particularly in the thriving two-wheeler service industry that maintains everything from humble Hero motorcycles to premium imports.

Compression Ratio: The Foundation of Performance

The compression ratio fundamentally affected engine performance and was adjusted during rebuilds or performance modifications.

Methods of Adjustment

Modifying compression ratio involved:

- Cylinder Head Milling: Removing material from the head to decrease chamber volume

- Different Thickness Head Gaskets: Changing the gasket thickness to alter chamber volume

- Piston Selection: Using pistons with different dome or dish configurations

- Cylinder Block Decking: Machining the block deck surface

Many mechanically-inclined enthusiasts in India would modify their motorcycles’ compression ratios to cope with varying fuel quality across different regions, particularly in remote areas where premium fuel might not be available.

Jetting for Altitude and Climate

India’s diverse geography, from the coastal plains to the Himalayan highlands, presented unique challenges for carburetion. Mechanics and riders had to understand how to adjust their vehicles for these varying conditions.

Environmental Considerations

Pre-ECU tuning required adjustments for:

- Altitude Changes: Higher altitudes required leaner jetting due to reduced air density

- Temperature Variations: Cold weather needed richer mixtures, hot weather leaner

- Humidity Effects: High humidity reduced the oxygen content in air, requiring slightly leaner mixtures

Riders traveling between Delhi and Ladakh, for instance, would often carry different jets to tune their motorcycles as they ascended through dramatic elevation changes.

The Tools of the Trade

Pre-ECU tuning required specific tools and equipment that skilled mechanics would accumulate over years:

- Vacuum Gauges: Measured intake manifold vacuum to assess engine efficiency

- Dwell Meters: Measured the time contact points remained closed

- Timing Lights: Stroboscopic tools for setting ignition timing

- Compression Testers: Assessed cylinder compression and engine health

- Mixture Analyzers: Basic devices that analyzed exhaust gas for tuning carburettors

- Tachometers: Measured engine RPM for synchronizing multiple carburettors

- Feeler Gauges: Used for setting valve clearances and point gaps

Many of these tools are still found in vintage motorcycle and car workshops across India, particularly in cities with active classic vehicle communities like Chennai, Pune, and Delhi.

Performance Modifications: The Creative Art

Beyond basic tuning, enthusiasts would modify their engines for increased performance through various mechanical means:

Common Modifications

- Port and Polish: Hand-finishing intake and exhaust ports for improved flow

- Camshaft Selection: Installing different profile camshafts for altered valve timing

- Exhaust System Design: Creating custom exhaust systems with optimized back pressure

- Intake Manifold Modifications: Polishing or replacing manifolds for better airflow

- Carburetor Sizing: Installing larger or multiple carburettors for increased fuel delivery

These modifications required extensive knowledge of engine breathing dynamics and how various components interacted. In India, this led to the rise of specialized tuning shops in major cities, many of which have now evolved to offer both mechanical and electronic tuning services.

The Balancing Act: Power vs. Reliability

One of the greatest challenges in pre-ECU tuning was balancing performance gains against reliability and drivability.

Tuning Compromises

Mechanical tuners needed to consider:

- Heat Management: Higher performance often meant more heat generation

- Fuel Quality Limitations: Modifications needed to account for available fuel quality

- Drivability Trade-offs: Racing-oriented tunes often sacrificed low-end torque and smooth idling

- Maintenance Intervals: Higher performance typically required more frequent maintenance

This balancing act created distinct tuning philosophies, with some Indian mechanics focusing on bulletproof reliability for rural applications while others pursued maximum performance for competitive events.

The Sensory Experience of Tuning

Perhaps the most remarkable aspect of pre-ECU tuning was how much it relied on the tuner’s senses rather than data alone:

The Mechanic’s Senses

Experienced tuners used:

- Sound: Listening for the distinctive sounds of proper combustion

- Smell: Detecting rich or lean conditions through exhaust odor

- Feel: Sensing engine vibration and throttle response

- Sight: Reading spark plug condition and exhaust color

- Touch: Feeling component temperatures and detecting abnormal operations

This multi-sensory approach created a deep connection between tuner and machine that many enthusiasts feel has been diminished in the digital age. Many young Indian enthusiasts still seek out older mechanics specifically to learn these sensory tuning skills, particularly those interested in vintage motorcycles like Yezdis, Jawas, and classic Royal Enfields.

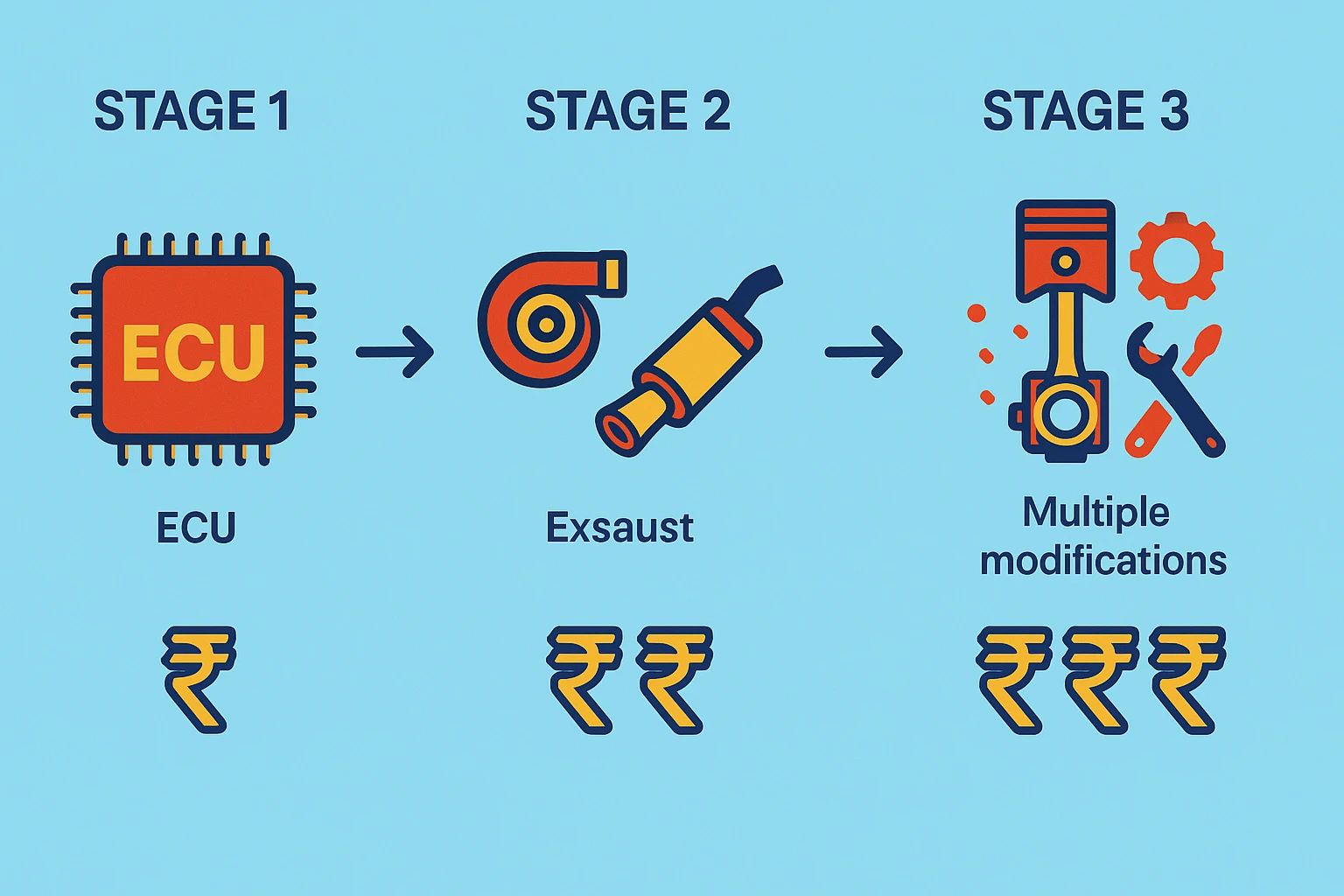

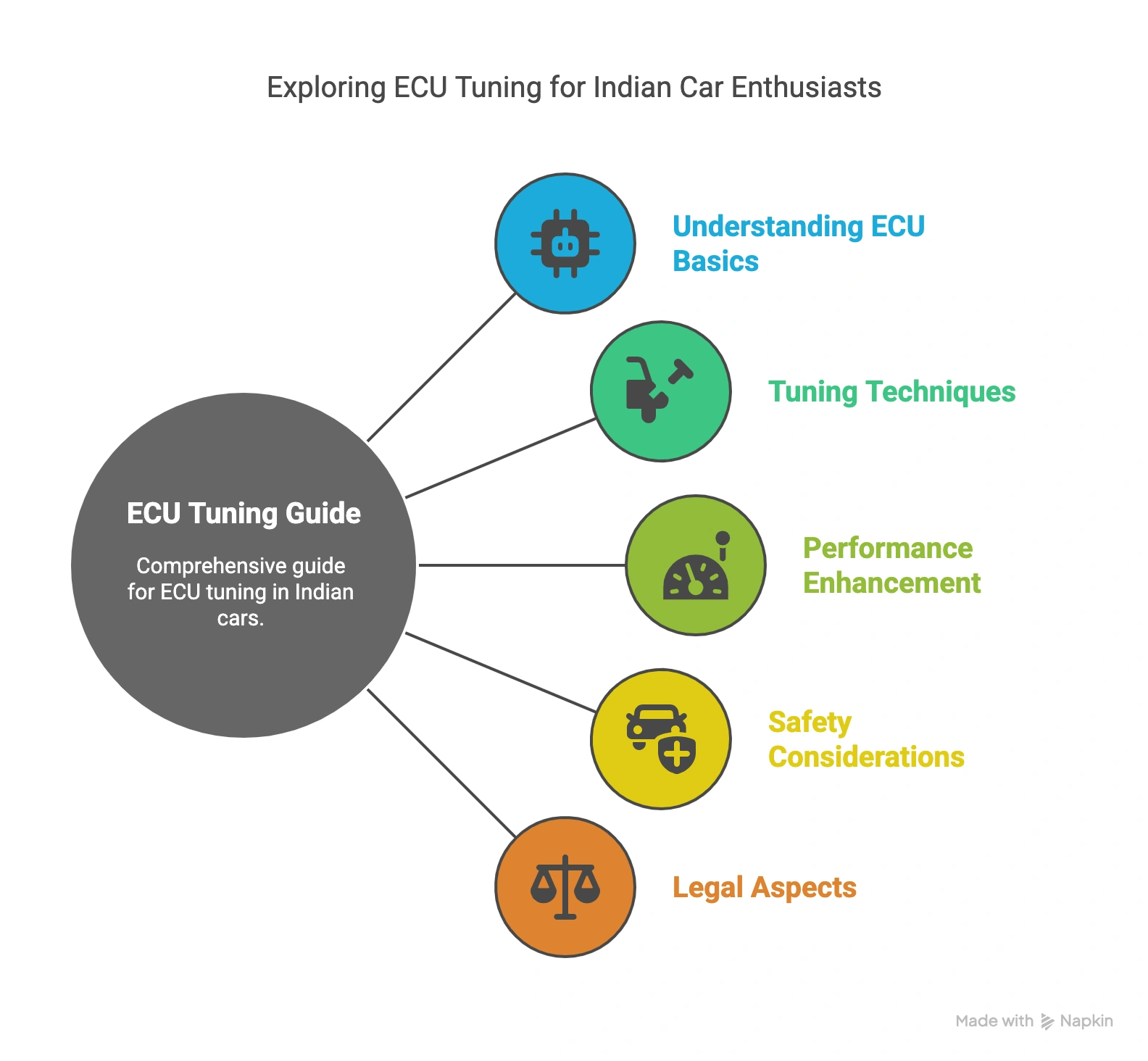

The Transition to Electronic Systems

The late 1980s and early 1990s saw the gradual transition from purely mechanical tuning to electronic systems:

Early Electronic Aids

Before full ECUs became standard, transitional technologies included:

- Electronic Ignition Modules: Replaced points with electronic triggers

- Transistorized Coil Ignition: Improved spark energy and reliability

- Rudimentary Fuel Injection: Early mechanical and simple electronic injection systems

These systems began appearing in premium vehicles in India in the 1990s, gradually filtering down to mass-market vehicles in the following decades.

The Legacy of Mechanical Tuning in Modern India

Today, mechanical tuning knowledge remains relevant in India for several important reasons:

- Vintage Vehicle Maintenance: The thriving classic vehicle scene requires these skills

- Rural Mechanics: In remote areas, mechanical skills remain essential for maintaining older vehicles

- Understanding Fundamentals: Knowledge of mechanical principles helps in understanding modern electronic systems

- Self-Reliance: The ability to tune without electronic diagnostic equipment remains valuable

Many automotive and mechanical engineering students in India still learn these fundamental tuning skills alongside modern electronic systems, creating a generation that bridges both worlds.

Conclusion: The Enduring Value of Mechanical Knowledge

While ECUs have revolutionized vehicle tuning with their precision and adaptability, the art of mechanical tuning represents an important chapter in automotive history that continues to influence modern practice. The skills, patience, and mechanical sympathy developed in the pre-ECU era have created a foundation for today’s tuning culture.

For young Indian automotive enthusiasts and engineering students, understanding these mechanical principles provides invaluable insight into engine operation fundamentals. Whether maintaining a classic Royal Enfield, restoring a vintage Hindustan Ambassador, or even tuning a modern motorcycle, the mechanical knowledge of previous generations remains an invaluable resource in the automotive world.

The next time you connect a laptop to your vehicle’s OBD port, spare a thought for the generations of tuners who achieved remarkable results with nothing more than basic tools, keen senses, and mechanical ingenuity. Their legacy lives on in the distinctive sound of a well-tuned carburettor and the satisfaction of mechanical perfection achieved through skill rather than software.