Introduction: Why Ignition Timing Matters

Ignition timing is one of the most vital elements in performance engine tuning. It governs the precise moment a spark plug fires in relation to the piston’s position in the cylinder. When calibrated correctly, ignition timing maximizes engine output, fuel efficiency, and longevity. If misaligned, it can lead to poor drivability, wasted fuel, or even catastrophic engine damage.

Benefits of Optimal Ignition Timing:

Boosted horsepower and torque

Smoother throttle response

Enhanced fuel economy

Lower emissions

Reduced engine wear

Longer engine life

With today’s advanced Engine Control Units (ECUs), ignition timing is dynamically controlled based on inputs such as RPM, engine load, air intake, and temperature. ECU tuning allows these parameters to be customized—unlocking untapped performance tailored to your goals.

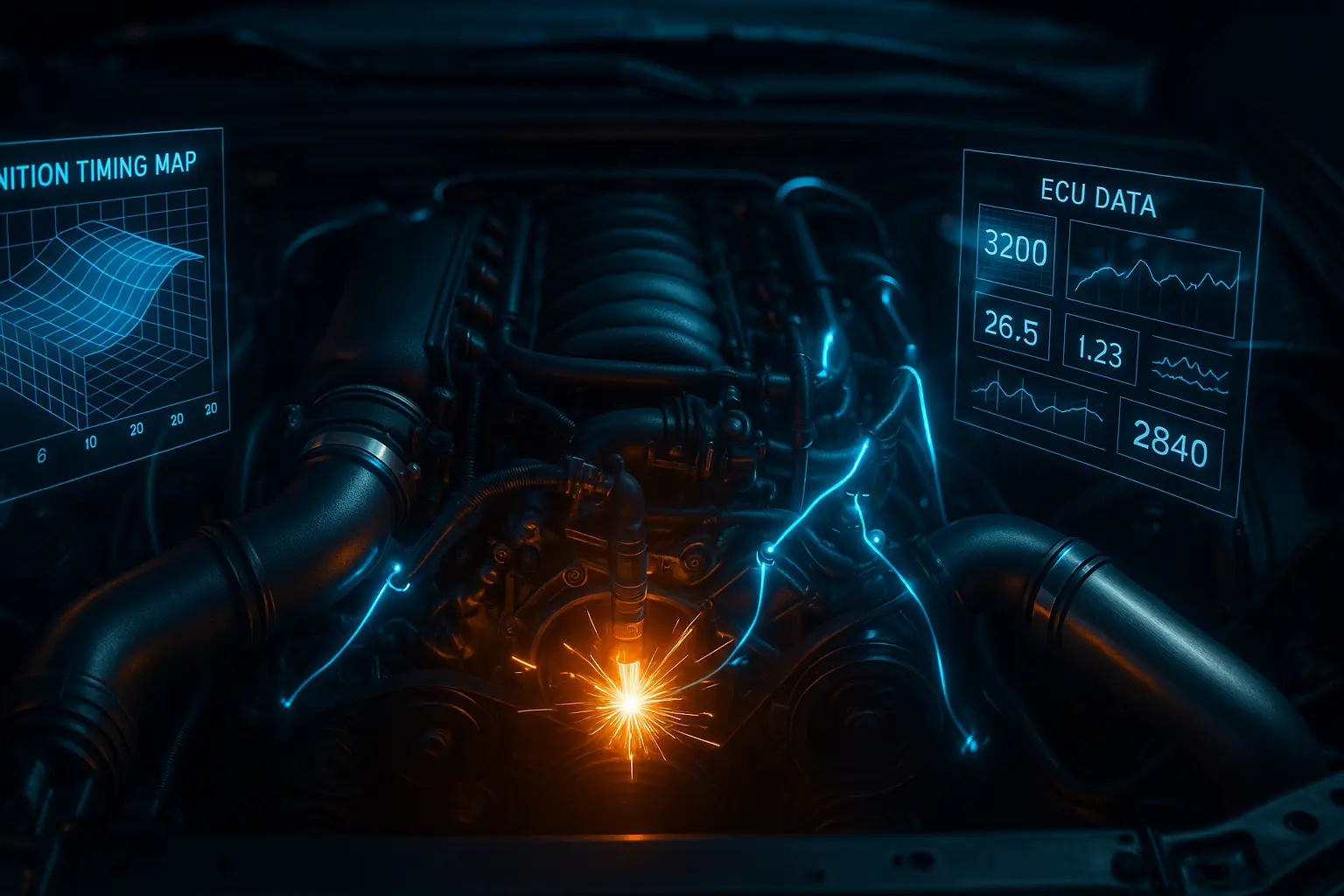

Understanding the ECU and Ignition Control

What Is the ECU?

The Engine Control Unit (ECU) is your vehicle’s brain, responsible for real-time engine management. It processes sensor data to control ignition timing and ensure efficient combustion across all operating conditions.

How the ECU Controls Ignition Timing

Modern ECUs use timing maps—3D tables that define when to trigger spark plugs based on RPM and engine load. Key sensors feeding this system include:

Crankshaft and camshaft position sensors

Knock sensors

Mass airflow and intake air temperature sensors

Throttle position and coolant temperature sensors

Oxygen sensors

Factory timing maps are intentionally conservative to support reliability, fuel variation, and emissions regulations—leaving room for safe, performance-oriented tuning.

The Science Behind Spark Timing

Combustion Dynamics

For peak power, the air-fuel mixture should reach maximum pressure at 15–20° after Top Dead Center (ATDC). Because combustion takes milliseconds to develop, the spark must fire before the piston reaches TDC—a concept known as spark advance.

Factors Influencing Optimal Timing

RPM: Higher RPM requires more advance due to shorter combustion time.

Load: Heavier load increases combustion speed; less advance is needed.

Air-Fuel Ratio: Lean mixtures burn slower (need more advance); rich mixtures burn faster.

Fuel Octane: Higher octane resists detonation—supports more advance.

Compression Ratio: Higher compression increases heat/pressure; usually needs less timing.

Combustion Chamber Design: Affects flame speed and ignition needs.

Intake Air Temperature: Cooler air is denser, affecting burn rate.

Detonation: The Hidden Danger

Also called knock or ping, detonation happens when the air-fuel mixture auto-ignites prematurely. This causes multiple flame fronts to collide, resulting in shockwaves that can destroy the engine.

Symptoms & Risks of Detonation:

Metallic pinging sound

Reduced performance

Broken piston rings or head gaskets

Catastrophic engine failure

Modern ECUs detect knock and automatically retard ignition timing to prevent damage—but smart tuning avoids even reaching that point.

Before You Begin: Tuning Prerequisites

Knowledge Requirements

Understand engine mechanics

Be familiar with your ECU system

Know how to interpret sensor data

Practice safe tuning techniques

Vehicle Readiness

Ensure engine is mechanically sound

Use the correct octane fuel

Fit fresh spark plugs (correct heat range)

Verify ignition system integrity

Confirm proper air-fuel mixture

Essential Tools & Software

ECU interface (e.g., OBD-II adapter)

Tuning software (HP Tuners, EcuFlash, Cobb AccessPort)

Wideband O₂ sensor for accurate A/F ratio

Knock detection tools

Datalogging system for real-time engine metrics

Step-by-Step Guide to ECU Ignition Tuning

1. Establish a Baseline

Record stock timing map values

Perform initial dyno pulls or acceleration tests

Log engine behavior across driving conditions

Document fuel usage for comparison

2. Research Factory Specs

Know OEM timing limits

Understand platform-specific quirks or safety margins

3. Initial Setup

Install and configure tuning software

Back up original ECU data

Locate and understand timing maps

4. Set Tuning Goals

Choose whether to prioritize:

Maximum power

Better mileage

Drivability balance

5. Adjust the Timing Map

Make 1–2° changes per cell

Focus on areas within typical RPM/load ranges

Test each change before moving forward

6. Validate and Refine

Monitor for knock

Check power and throttle response

Fine-tune map with 0.5–1° increments

Test under various temperatures and loads

7. Final Validation

Confirm gains with dyno runs or road tests

Observe cold-start, warm-up, and fuel economy

Perform emissions testing if required

Advanced Ignition Timing Strategies

Multiple Timing Maps

Some ECUs support:

Temperature-specific maps

Octane-selectable maps

Boost-based adjustments (for turbo/supercharged engines)

Dynamic Timing Adjustments

Intake temperature compensation

Adaptive learning from knock sensors

Altitude-based timing correction

Cylinder-Specific Timing

High-end ECUs allow precise spark timing per cylinder—helpful for:

Addressing uneven intake/cooling conditions

Managing knock-prone cylinders

Optimizing power distribution

Troubleshooting Common Timing Issues

| Issue | Symptoms | Fix |

|---|---|---|

| Detonation/Knock | Pinging under load, timing retard, power loss | Reduce advance, use higher octane, lower temps |

| Retarded Timing | Poor mileage, low power, hot exhaust, laggy throttle | Add advance, verify sensors, check for exhaust blockages |

| Inconsistent Timing | Surging idle, jerky power, throttle hesitation | Smooth maps, fix sensor faults, stabilize transitions |

Safety & Legal Considerations

Protecting Your Engine

Avoid large timing jumps

Monitor knock in real time

Be cautious in low-RPM, high-load scenarios

Environmental and Legal Compliance

Aggressive timing may increase emissions

Stay compliant with local ECU modification laws

Keep a street-legal tune for inspections

Top Tuning Tools & Gear

Professional Software

HP Tuners: Best for American vehicles

Cobb AccessPort: Ideal for Japanese/European sports cars

EcuFlash: Open-source option with community support

Monitoring Devices

AEM UEGO / Innovate LM-2: Air/Fuel Ratio

Knock Detection Systems: “Knock ears,” mics, or digital tools

OBD-II Scanners: For logging engine vitals

FAQs: ECU Ignition Tuning Explained

Is ECU tuning the same as “chipping”?

No. Chipping involved swapping hardware chips. Modern tuning reprograms the existing ECU software.

Can ECU tuning void my warranty?

Yes—if detected, manufacturers may reject warranty claims linked to modifications.

What performance gains can I expect?

Typically, 5–10% power increases from ignition timing optimization alone.

Do I need a dyno to tune?

Not necessarily. Street tuning is possible but requires proper tools and caution.

Can beginners do this?

Only if you’re technically confident. Otherwise, work with a professional tuner.

How often should I re-tune?

After any major engine change or if performance noticeably drops.

Conclusion: Fine-Tuning for Power, Safety, and Efficiency

ECU tuning for ignition timing is one of the most impactful adjustments you can make to enhance your vehicle’s performance, fuel economy, and responsiveness. It’s both an art and a science—requiring knowledge, patience, and precision.

With the right tools and techniques, you can transform a factory-limited tune into a custom-calibrated setup that reflects your exact driving goals. Whether you’re chasing lap times or better mileage, mastering ignition timing tuning will bring measurable gains and deeper insight into your engine’s inner workings.